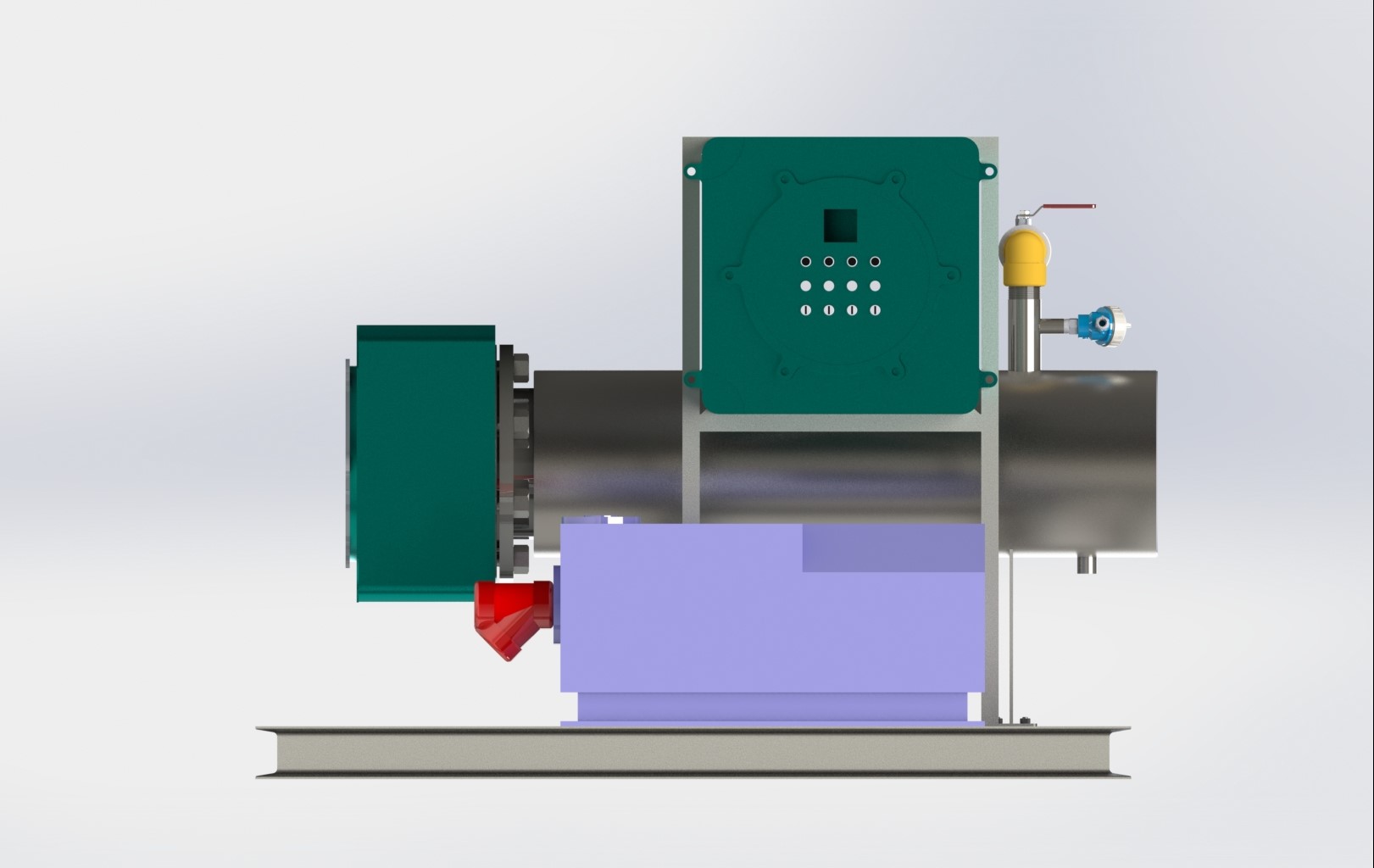

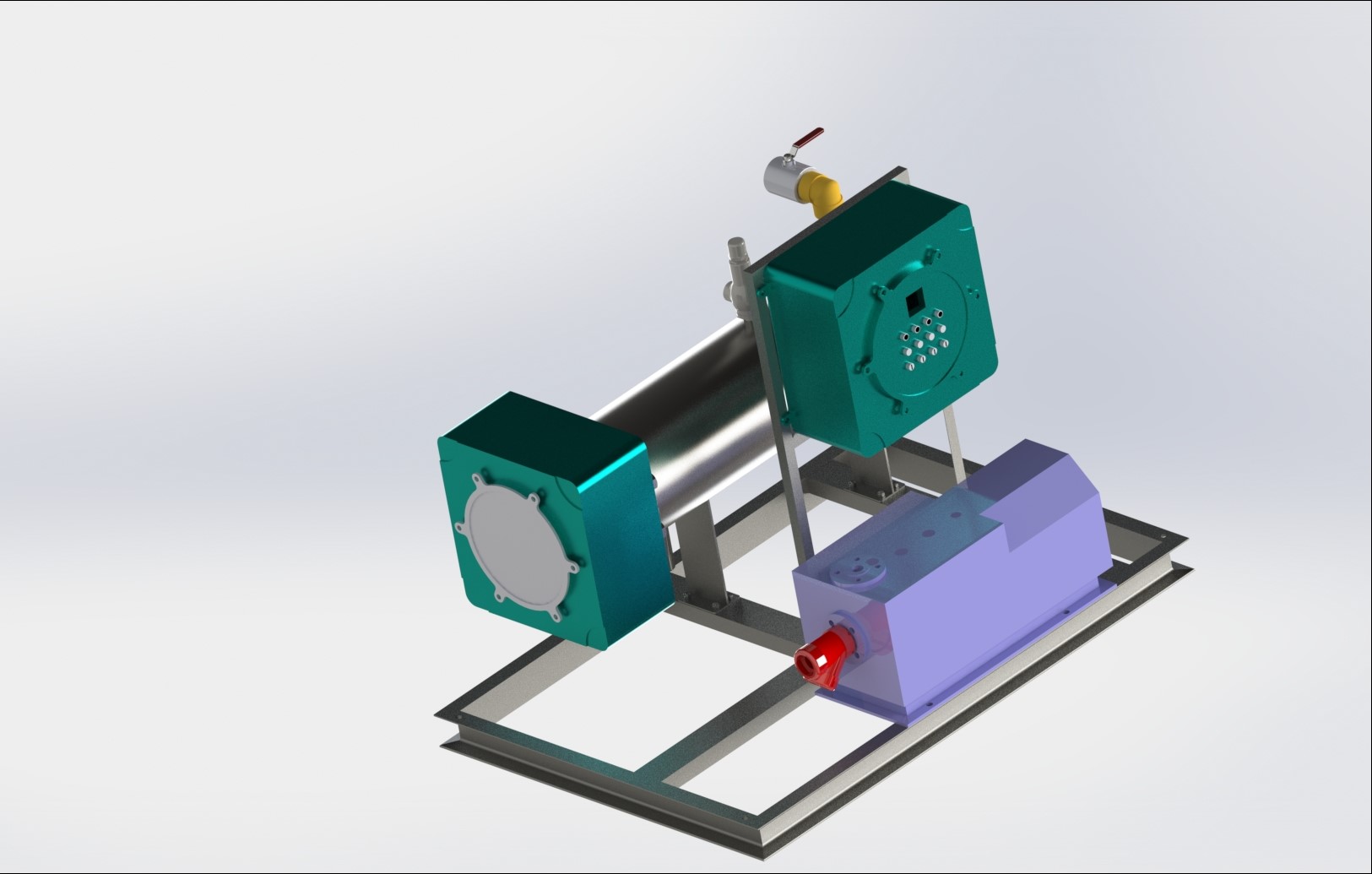

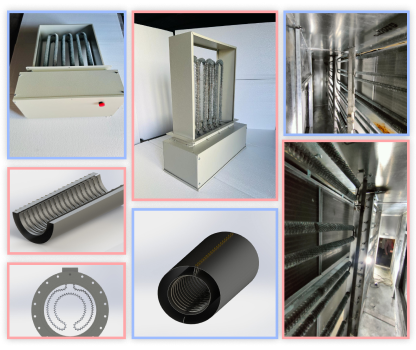

Terminal Box

In a process heater, the terminal box act as an enclosure for electrical connections and components related to the heating system. Below are the breakdown of its purpose and components: The terminal box provides a protective enclosure for electrical connections, wiring, and components associated with the process heater. It helps to prevent exposure to dust, moisture, and other environmental factors that could potentially damage the terminals of heating system

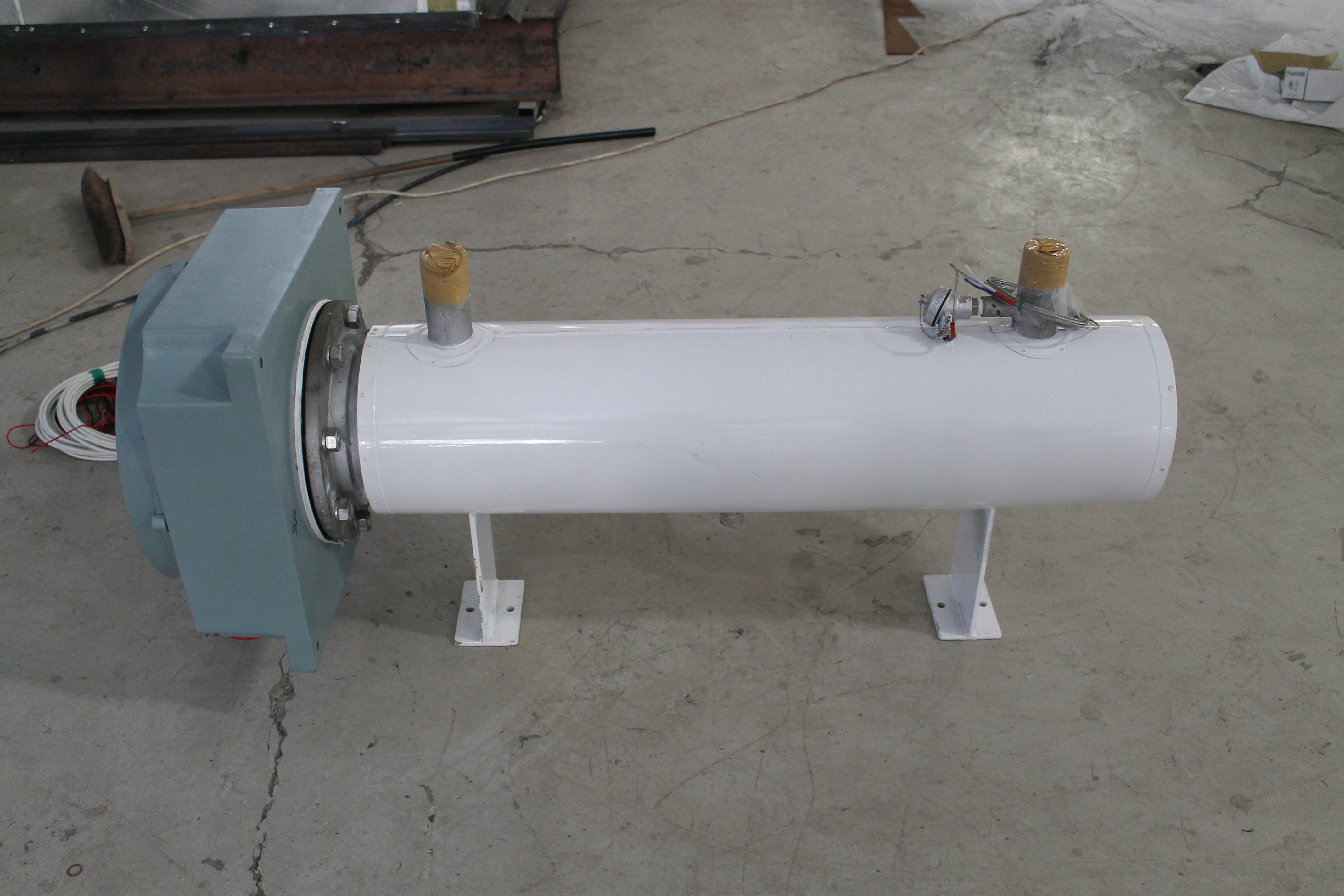

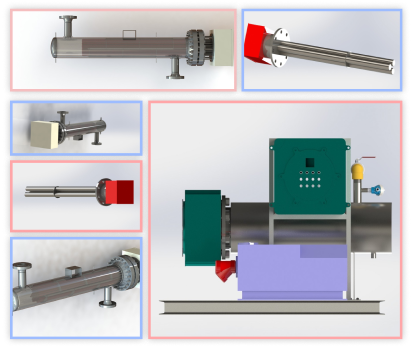

Fluid Circulation Shell

Shell handles circulation fluid and electrical heater enclosed within the shell. Shell handles extreme pressure from 1 – 50kg/cm2 to accommodate fluid and temp. Rise of fluid. Fluid moves turbulently between the heater and shell. Inlet & Outlet nozzles are welded to the shell area and safety valves also attached to it to make the heating process run smoothly.

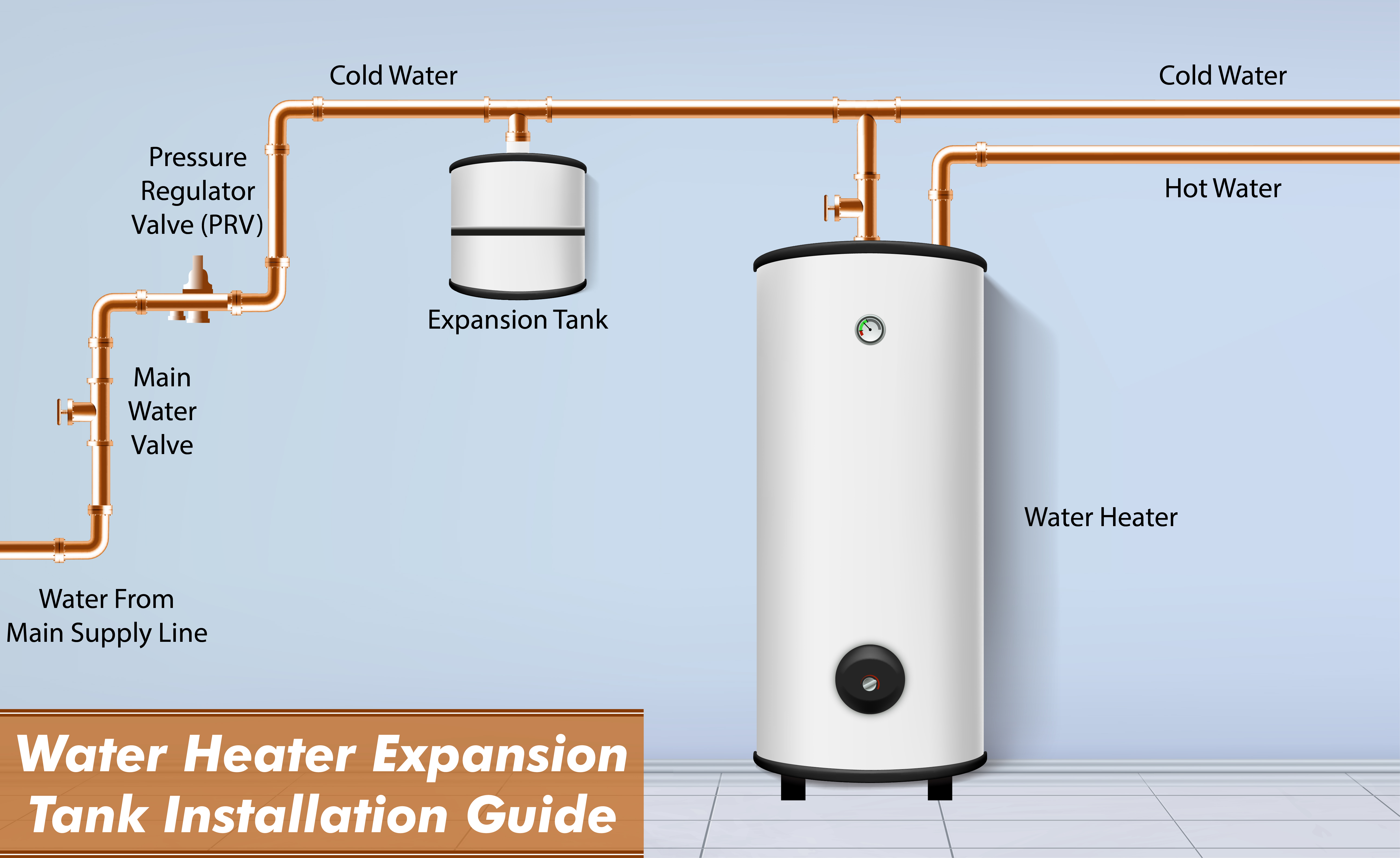

Expansion Tank

In a process heater system, an expansion tank serves a vital role in managing the thermal expansion of the heating fluid. Here's a break down of its purpose and function:

Circulation Pump

The fluid has to be circulated continuously through complete process equipment and sent to the targeted area where the actual usage of fluid happens. To make this process happen pump has to withstand the original fluid temp. Which is higher than normal in order to facilitate circulation.

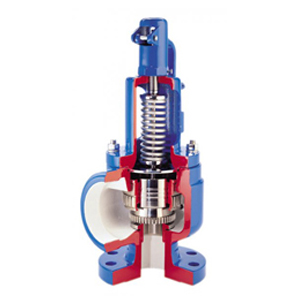

Safety Valves

Safety valves are essential components inprocess heater systems designed to protect equipment and personnel fromoverpressure situations

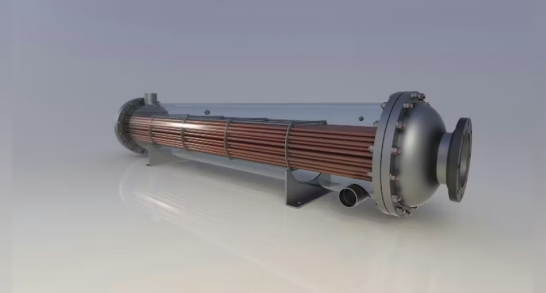

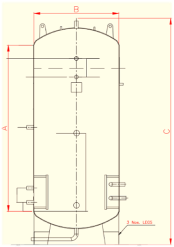

Calorifiers Storage Tank

Storage Calorifiers are manufactured in two categories such as Direct Heating which is equipped with Electric Immersion Heaters or Indirect Heating which is using Heat Exchanger Tubes (spiral tube hex or u-tube hex). Mainly applicable for Domestic Water Heating System

Tank Dish end

A tank dish end, also known as a tank head or tank cap, is a component used to close or seal the ends of cylindrical pressure vessels such as tanks, boilers, and reactors. These ends are curved in shape, resembling a portion of a sphere or ellipsoid, and are welded or bolted to the cylindrical body of the vessel. Tank dish ends serve several important functions in pressure vessel design and operation:

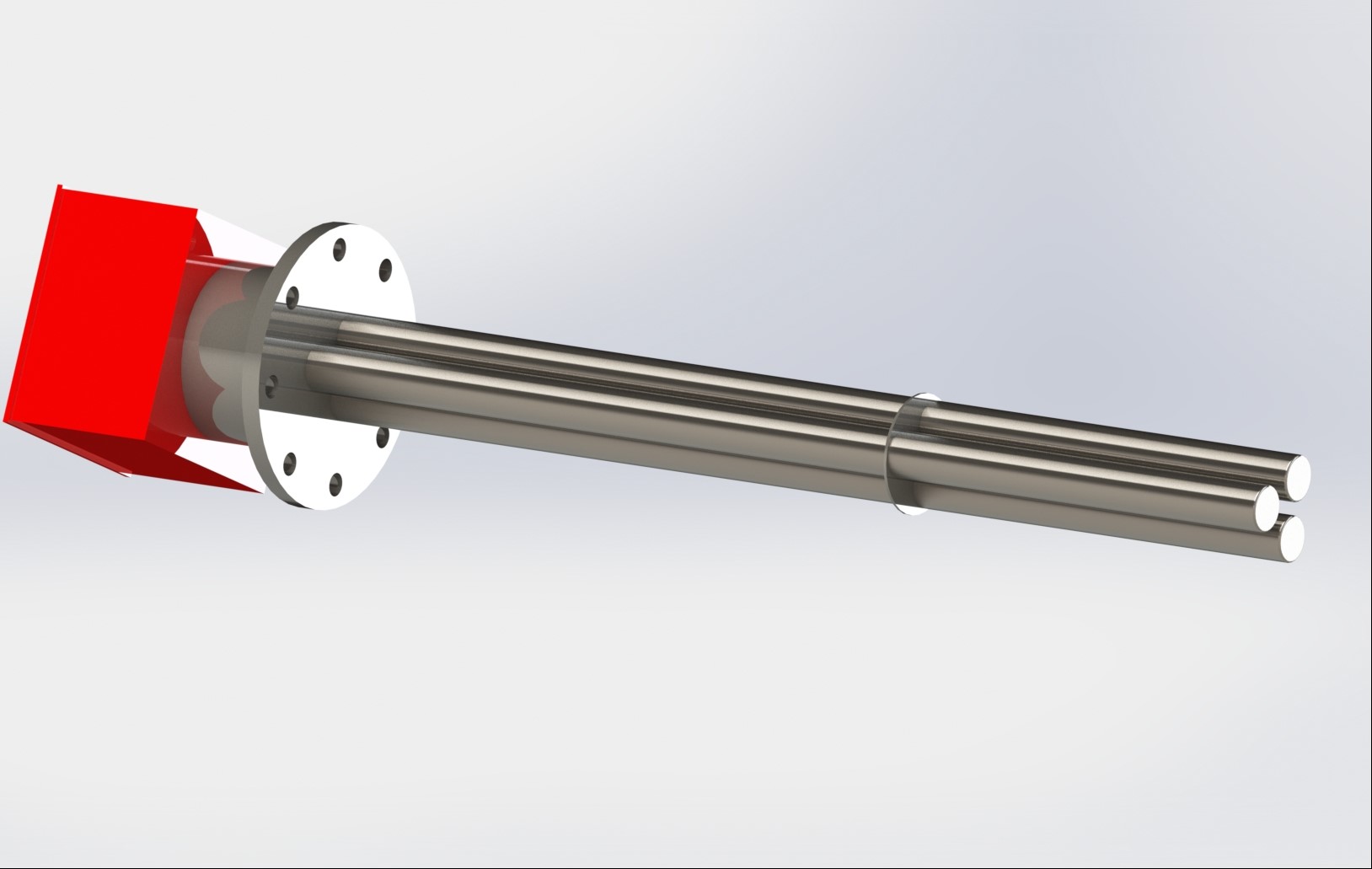

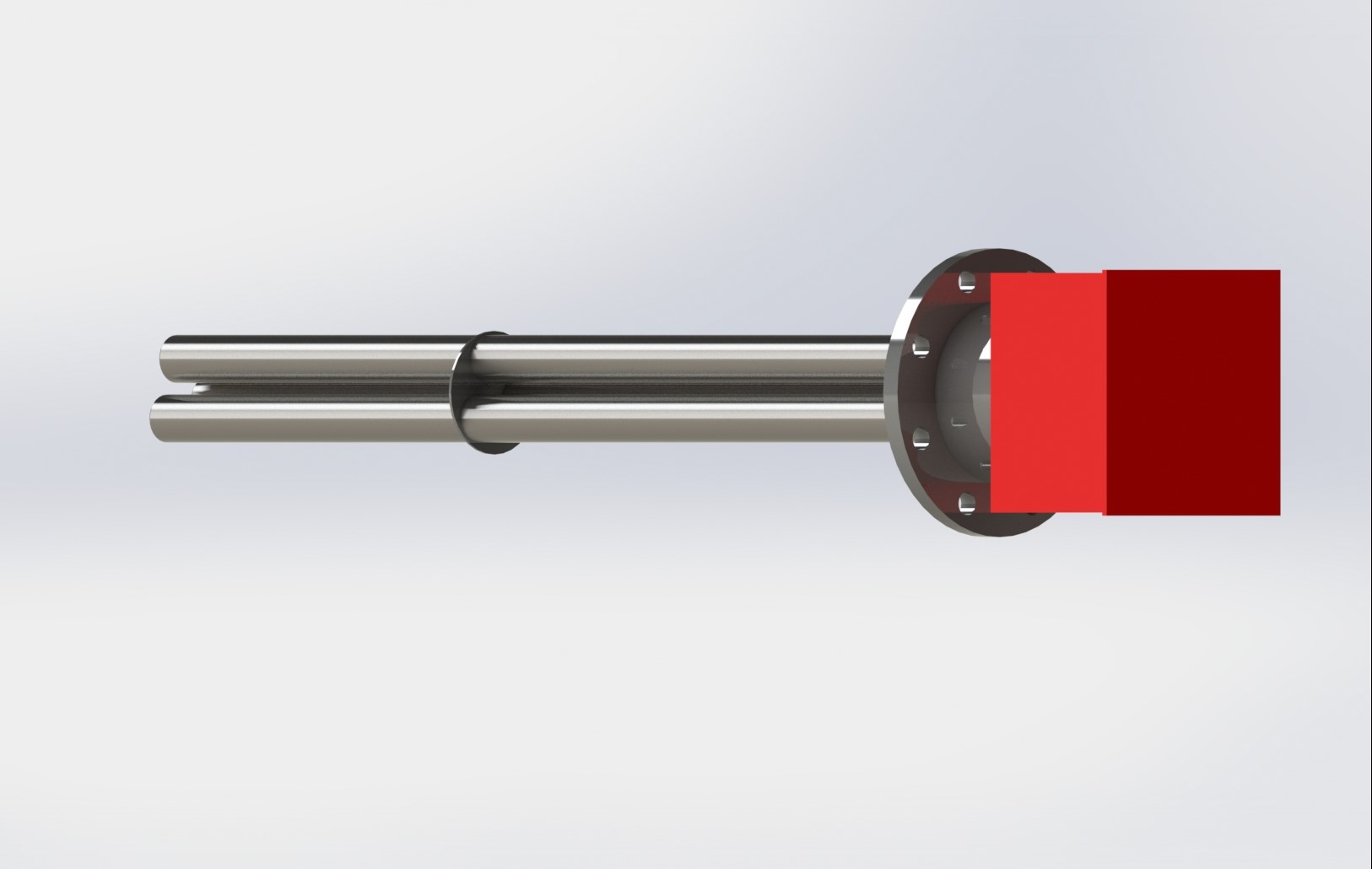

Electric Heater / Heat Exchanger

An electric heater in a calorifier tank typically consists of one or more heating elements immersed directly in the water or fluid. These heating elements are usually made of materials with high electrical resistance, such as nichrome or stainless steel, which generate heat when an electric current passes through them.

Safety valves & Vent

Step Controller For high power range applications duct heaters are available with electronic step controller if required. They are used to stage multiple steps of electric or pneumatic control. Switching multiple stages with step controller ensures that the room set point should not take stress as load requirement changes. SCR Controller Heat bird also provides duct heaters along with SCR controls. One hundred percent solid state proportionating control is noiseless and does not have any mechanical device. SCR controlled duct heaters can be able to provide very fine and precise temperature environment which can be having highest reliability. Modulation from 0 to 100% can be achieved by time based proportional firing which can be varied in response to the various thermostat demands. Insulated Control Panel: Insulation is recommended betweencontrol panel and heaters for higher temperatures. Insulation material will be installed between panel and hot surface area to prevent condensation on electrical components. Bottom Control Panel: Bottom control panel can be supplied when required for easy installation and maintenance. Remote Control Panel: In some case it is advisable to install panel remotely from heating elements. It is also supplied as per requirement which enable to operate the heater from remote locationlike control room, etc.

Other Categories

Air Heating Solutions

Learn more

Liquid Heating Solutions

Learn moreKnow what you’re looking for?

Lorem ipsum dolor sit amet consectetur. Elementum etiam commodo pharetra ultrces risus platea varius integer ornare. Morbi rhoncus ut dolor in leo dolor ut rutum. Id isum praesent lacus sodales aliquet erat libero. Morbi blandit arcu at aliuet rutrum aliquam.